You're almost ready to complete your order. Before you do though, please be sure to read through this checklist and make sure everything is accurate. While this checklist doesn't cover all measuring tips for each item, it does address the more common issues we come across when reviewing an order.

General Tips

→ You've selected the appropriate material for the right space.

Stainless steel items will need to be used for high humidity/wet areas including for use outdoors, in bathrooms, and in kitchens. You’ll also want stainless steel parts if you’d like the Brushed Stainless of Glossy Brass finish.

→ All items in your order are the same material.

Normally, you’ll want all items in your order made of stainless steel, OR all items made of steel.

→ All of your Bypass Hardware is from the same manufacturer.

If you need bypass hardware, then it is highly recommended to get the rod, bypass brackets, and C-rings from us. Bypass parts are precision aligned and mixing parts from different manufacturers will not normally work.

Rods Checklist

→ For double rods, has enough space has been allowed between rods?

When specifying clearance on the rods and/or double brackets, be sure to allow enough space between the two rods. We recommend 1 1/2" space between rods, but you may need more depending on fabrics, ring spacing, etc.

For example:

- Back Rod: 1" diameter, 2 1/2" clearance

- Front Rod: 1 1/4" diameter, 5" clearance

The back rod would start at 2 1/2" and end at 3 1/2", and with 1 1/2" spacing the front rod will start at 5".

→ For rods with returns, have you ordered 2 Post brackets?

Rods with returns require Post brackets to mount to the wall, so be sure to order 2 Post brackets for each return rod. If you’d like a return on only one one end of the rod, we can do so, just let us know which end of the rod needs the return (call or email after placing your order).

→ Have you double checked the span between brackets.

"Span" is the distance between two adjacent brackets. For example, a 130" rod with one middle bracket would have 2 spans of 65". A 90" rod with no middle bracket would have a span of 90".

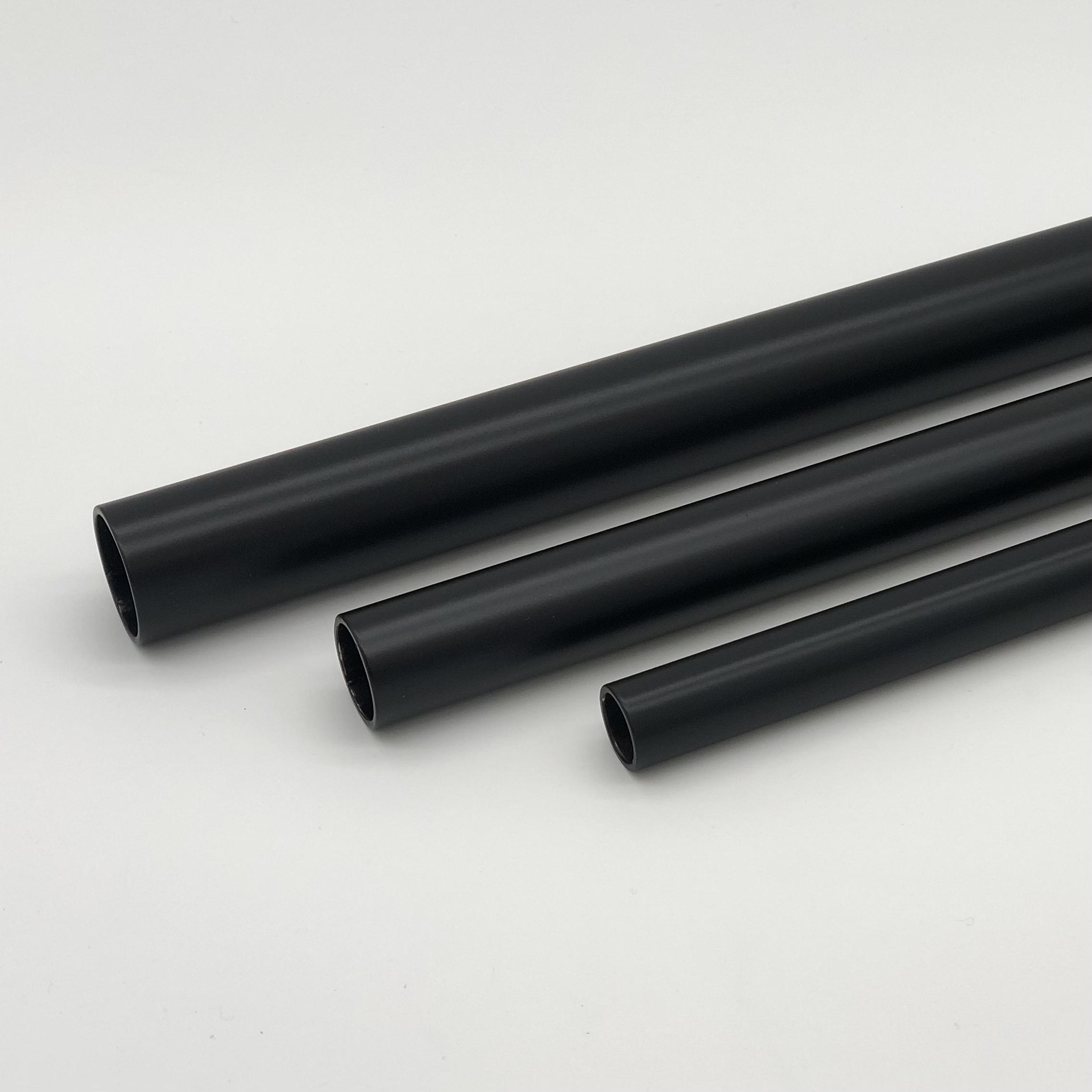

Knowing the span(s) of the rod will help you determine what diameter you need. Rods increase in rigidity as they increase in diameter, therefore the longer the span, the larger diameter rod you will need to prevent sag. Fabric weight should also be considered.

Please see our Tips for Extra Long Rods resource page for the maximum suggest span (distance between brackets) for each rod diameter.

Brackets Checklist

→ How many brackets do you need?

For any rod, you will need at least the following number of brackets:

- Straight rods less than 105" = 2

- Straight rod between 105" and 210" = 3

- Corner rod = 3

- Bay rod = 4

- Bow rod - 3

These are just the bare minimum quantities. Please see our Tips for Extra Long Rods resource page for maximum suggest spans to determine if you will need additional brackets.

→ Are you ordering Socket Brackets?

If so, make sure to subtract 7/8" from the wall-to-wall measurement to allow room for the socket bracket backplates. This allows room for the brackets themselves (the backplates are 3/8" thick) and an extra 1/8" for ease of installation.

→ Are you using Bypass Brackets?

If so, these are used with the C-rings to allow easy sliding past a bracket.

Rings Checklist

→ Did you select the proper ring size?

Rings should typically be 1/2" larger than the rod size, such as 2" ring with a 1 1/2" rod. You can use rings that are only 1/4" larger than the rod in most cases, so long as you do not have Mitered Returns, Bypass brackets, or intend to use Through-Ring wands.

In the case of a 1 1/2" or 2" rod with Mitered Returns you must use a ring 1" larger than the rod in order to slide around the mitered corner. (Although, if the rod is long enough to be spliced you can use smaller rings and load them from the middle splice joint at time of installation.)

→ Are you using C-Rings?

If so, make sure you are using Bypass brackets, and the C-Ring indicated for your rod size.